Pneumatic Modulating Valve

Overview

The control valve plays an important role in the loop adjustments, in the automatic control of industrial processes.

Performs the function of varying the flow of control fluid, which modifies the value of the measured variable, behaving like a continuously variable area orifice. Within the control loop is as important as the primary

element, the transmitter and controller. The shutter control performs the function of fluid flow, acting in the direction of its axis.

Shutter equal percentage:

In a shutter with equal percentage characteristic, every increment of stroke in the shutter produce a change in the flow that is proportional to the one that flowed before the change.

Gaskets are used isopercentual valves for:

• Fast processes.

• When the system dynamics are not well understood.

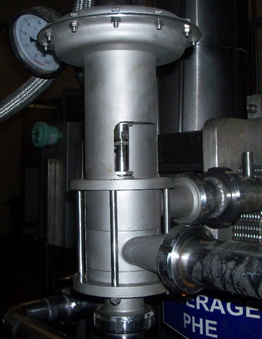

Globe Valve

Valve whose construction is distinguished by controlling the flow through a linear movement.Valve with single seat and 2 ways.

Single seat valves require a larger actuator for closing the shutter against the differential pressure of the process.

The tight closure is achieved with stainless steel shutter and PPL seat.

Normally Closed Control Valves (Spring Return)

Drive: pneumatic (air to open)

Features:

Body material: SS304, SS316 (Made out of solid stock for robust structure)

Connection: Flanged ends, threaded, SMS Union, Triclover

Limit of pressure: Water 16 bar at 120ºC

Steam 13 bar at 200ºC

Working Temperature: -20ºC / + 230ºC

Diaphragm type, spring return, normal close.

Maximum input pressure: 10 bar.